Size Reduction Technology – Interview: “Digitisation Creates High Transparency”

Getecha Managing Director Burkhard Vogel about Industry 4.0 in Granulating Technology In many plastics processing industry sectors, the production-related integration of granulation technology in injection moulding, extrusion, blow moulding and thermoforming lines is advancing rapidly. The granulator manufacturer Getecha responded to this trend at an early stage and now equips the hopper and infeed granulators of its “RotoSchneider” series with numerous intelligent functionalities according to Industry 4.0 criteria. Managing director Burkhard Vogel explains in an interview what is important.

Mr. Vogel, how significant is the equipping of Getecha granulators with Industry 4.0 functions currently for your development engineers? Burkhard Vogel: In addition to the continuous innovation pro- cess for optimising the central performance components for the rotors, the cutting chamber as well as the infeed and dis- charge systems, the development of useful Industry 4.0 func- tions for our granulators has gained enormously in importance, especially in the last three to four years. This applies to the series with the small and compact beside the press granulator series as well as to the large central granulators and the infeed granulators. What do you think is the decisive factor here? Vogel: Whether you consider the automotive industry and its suppliers, the manufacture of packaging materials or the large sector of the consumer products – in all industries the desire for further automatisation is pushing the digitalisation of produc- tion processes. The realisation of structures according to the standards of Industry 4.0 does not stop at the fields of material conditioning and granulation technology. Our engineers recog- nised this several years ago, so that we have already been able to build up a considerable know-how in this area and are now able to equip our RotoSchneider granulators with a range of in- telligent information and communication features.

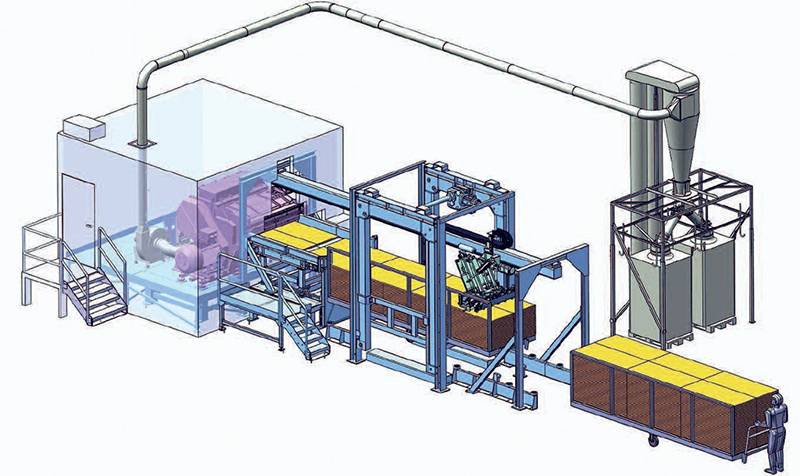

Ê re these Industry 4.0 functionalities meanwhile parts of the standard equipment of granulators? Vogel: Not in all cases. Industry 4.0 functionality only gets into the focus of a customer when he wants to integrate granula- tion technology into his mainly automated processes of plastics processing. When this occurs, the information and communica- tion technology integration of the granulators into the produc- tion technology infrastructure plays a central role, so that their efficiency and availability can also be secured on a digital level. Can you be more specific about this aspect? Vogel: Imagine a plastics processor with the intention of inte- grating one or even several of our central or beside-the-press granulators into his material flow and automated production processes using conveyor belts, tilting devices, filling stations and other peripheral systems, in order to return residues and waste to production via a recycling circuit in a resource-saving manner. . s part of such a project, various Industry 4.0 features in our granulators can provide valuable services. This is because it not only supports continuous system optimisation, but also serves quality assurance, allows process-accompanying moni- toring and can significantly improve the availability of a produc- tion line. Which Industry 4.0 functions should a granulator be equipped with in any case? Vogel: This is decided based on the concrete requirements of a project and the customer’s goals. Many things are now feasible because we use numerous possibilities of modern sensor and interface technology as well as a range of established field bus systems. In this way many important process and machine data can be tapped, documented, processed, visualised and evaluat- ed. Do you have an illustrative example of this? Vogel: If the signal exchange between granulator and produc- tion line is configured, all statuses, actions and error events can be recorded and assigned. Based on this, critical situations can be reported with defined warning levels to the higher-level pro- duction control system, which then initiates suitable counter and corrective measures at an early stage. In addition, it is pos- sible to record all production-relevant performance parameters and material key figures of a granulator – such as throughput or the quality of the ground material – and to send them to the Operating Data a cquisition or Major Diagnostic Category sys- tems of the plastics processor for further evaluation. This also applies to the runtimes, energy consumption, performance peaks and many other parameters from the operation of the granulators. We can also arrange for all system messages to be communicated to the host computer and archived there for analysis and documentation. . ll this creates maximum transpa- rency about the performance of an automated system. So the plant operator also receives data on the imple- mentation of important process and quality improve- ments? Vogel: Correct. Not least because part of the data material pro- cessed via the signal exchange between the production line and the granulating plant is also available for Industry 4.0 functions, which enable a so-called Predictive Monitoring and increase the plant availability. For example, much of the collect- ed information can be prepared for predictive maintenance and then retrieved by the Getecha remote maintenance tool. For this purpose, the granulators can be linked and integrated into the customer’s MRO infrastructure. The knowledge gained from this also flows into the troubleshooting catalogue of the integrated “manual” of the Getecha granulators. The master control system of the production machine can then display this information to the operator. What specific industry 4.0 projects is Getecha currently working on? Vogel: Well, these are ongoing projects with customers, and I cannot reveal too much about them. But I can tell you that whether it is about the waste from the extrusion of thick poly- propylene sheets, faulty parts from the thermoforming of cof- fee capsules or edge trims from film production – in many places Getecha granulators with Industry 4.0 functions are now an established part of production lines. Digitalisation – in addition to the selection of the appropriate rotors, drives, hoppers and many other components – is now a major factor in the customer-oriented design of our granulators. . nd we firmly expect that this topic will continue to gain in importance in the future

KEPT MACHINE is professional supplier for production line in field of plastic extrusion industry.

We help customer’s factory to improve their Pvc Extruder production and product.